|

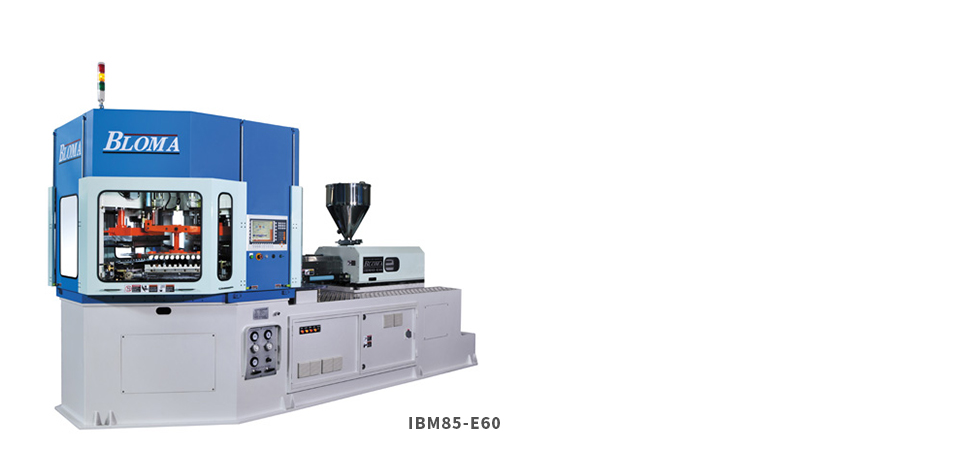

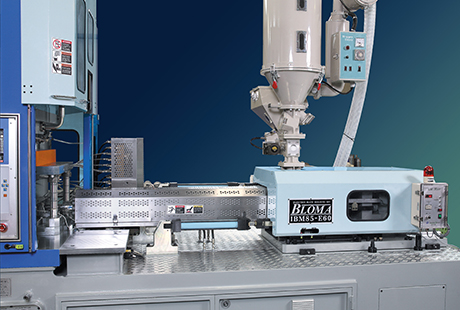

IBM Series

Front runner with proven credential in manufacturing highly advanced ibm machines using modern technology.

BLOMA is one of the pioneers in the field of manufacturing superiorly designed “STATE OF THE ART”IBM Machines in accordance with safety standards. IBM Machines are designed for ensuring mass production of bottles & container having excellent quality surface finish, precisely calibrated neck, air tight containers with absolutely no generation of scrap.

Features

- Unique machine design ensure reduction in cycle time, energy savings and reduction in floor space.

- Solid steel structure to main base frame guaranteeing full rigidity, stability and reliabilities.

- Operational excellence and stable control system.

- Specially designed Injection & Clamping bring high energy efficiencies with full accuracies even in peak speed mode.

- Multi safety devices incorporated in Mechanical, Electrical, Hydraulic Operations ensures Mold protection and Operator Safety.

- Quick & Safe Mold Changing on account of easy accessibility and with change over operations facing on operator side.

- Flexibility for using Molds used on other IBM machines.

- Sliding safety doors are useful for mold changing and performing manual operations with minimum space utilization

- during installation process.

- Ease of maintenance and replacement of spares due to visually clear accessibility of all parts & components.

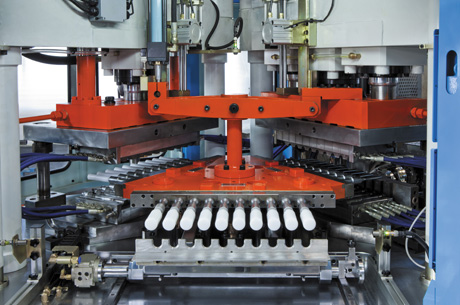

Camping unit with Indexing unit

- 3 Point High Stiffness Vertical Clamping Unit facilitates unit wise

uniform clamping force ensuring minimized mold abrasion.

- Highly precised indexing device results in to high speed

performance ensuring improved machine life with full reliability.

- Designed to assure high precision and accuracies even under

thermal expansions and with varying clamping forces.

- Swift mold change on account of Wide & Fixed Tie Bars.

- High safety standards by incorporating positioning sensors and

safety devices for Mechanical, Electrical, Hydraulic operations

as well as Mold Safety Devices.

- Laser Sensors for Bottle Ejection with full protection of Core Rods.

- Proven technology to successfully blow even intricate and

critical shapes of bottles with full dimensional accuracies

for ever changing needs of Cosmetic & Pharmaceutical industries.

Injection unit

- Optimized Injection conditions even under high injection speeds and low injection pressures

- Multiple Injection Control System(time, distance, speed & pressure)ensures precise and excellent Injection Consistencies.

- Equipped with Linear Motion Bearings on moving Injection unit guarantees accurate injection control with full reliability.

- PID Control 6 Zones temperature control arrangement provides operation consistency during injection operations.

- Use of highly advanced Ceramic Heaters and Cooling fans maintain desired temperatures at every stage of heating and cooling operation.

Control system

- User friendly energy efficient Micro processor Control with touch screen control system and easy to understand graphic screens.

- 10.4″LCD Touch Color Monitor.

- PID Temp. Control Function.

- Easy Statistical way of controlling & managing product quantity & quality settings.

- Self Diagnosis and monitoring functions.

Specification

| Item | IBM-40 | IBM-65 | IBM-85 | IBM-135 |

|---|

| Screw Diameter (mm) |

Ø45 |

Ø50 |

Ø55 |

Ø60 |

Ø70 |

| Max. Shot Volume (HDPE, g) |

180 |

240 |

310 |

380 |

560 |

| Preform Mold Clamping Force (tons) |

35 |

50 |

70 |

115 |

| Blow Mold Clamping Force (kn) |

7 |

14 |

14 |

24 |

| Max. Swing Radius (mm) |

500 |

650 |

650 |

880 |

| Trigger Bar Length (mm) |

305 |

550 |

550 |

915 |

| Max. Die Set Size (mm) |

W450 X L390 |

W622 X L432 |

W622 X L432 |

W902 X L483 |

| Mold Height (mm) |

228.6 |

228.6 |

254 |

254 |

| Mold Opening Stroke (mm) |

120 |

135 |

145 |

160 |

| Oil Pump Driving Motor (kw) |

27 |

34 |

41 |

41 |

60 |

| Total Connected Load (kw) |

39 |

49 |

57 |

61 |

86 |

| Average Power Cconsumption (kw) |

26 |

33 |

38 |

40 |

57 |

| Compressed Air at 10bar (㎥/h) |

20 |

34 |

38 |

55 |

| Mold cooling Water : 10℃-5bar (㎥/min) |

1.9 |

2.6 |

2.8 |

3.8 |

| Oil Cooling Water : 15℃-5bar (㎥/min) |

3.2 |

4.2 |

4.4 |

5.7 |

| Total Cooling Requriment (kj/h) |

170000 |

240000 |

260000 |

320000 |

| Machine Size |

Width (mm) |

1520 |

1805 |

1805 |

2250 |

| Length (mm) |

4050 |

4805 |

4805 |

5700 |

| Height (mm) |

2350 |

2550 |

2550 |

2650 |

| Machine Weight |

2350 |

2550 |

2550 |

2650 |

Production Possibilities

| x |

|

|

|

|

|

|

|

|

|

|

Dropper |

Cylinder Round |

Roll-on |

Powder |

Blake Jar |

Oval Jar |

Ovel |

Widemouth |

|

15ml |

30ml |

120ml |

150ml |

500ml |

50ml |

100ml |

100gr |

400gr |

100ml |

200ml |

70gr |

175gr |

200nl |

500ml |

100gr |

500gr |

| Material |

LDPE |

LDPE |

HDPE |

HDPE |

HDPE |

HDPE |

HDPE |

HDPE |

HDPE |

pp |

HDPE |

pp |

pp |

HDPE |

HDPE |

pp |

pp |

| Cycle |

10±1 |

11±1 |

11±1 |

12±1 |

15±1 |

12±1 |

12±1 |

13±1 |

15±1 |

10±1 |

11±1 |

12±1 |

13±1 |

14±1 |

15±1 |

14±1 |

16±1 |

| Weight |

4 |

6 |

12 |

22 |

32 |

11 |

16 |

12 |

34 |

14 |

22 |

11 |

21 |

24 |

40 |

18 |

47 |

| CAvtation |

IBM40 |

8 |

8 |

4 |

3 |

2 |

6 |

4 |

6 |

|

4 |

3 |

4 |

3 |

2 |

|

2 |

|

| IBM65 |

14 |

14 |

8 |

6 |

4 |

6 |

6 |

8 |

4 |

6 |

5 |

6 |

5 |

4 |

3 |

6 |

3 |

| IBM85 |

14 |

14 |

10 |

8 |

5 |

6 |

6 |

8 |

5 |

8 |

7 |

6 |

6 |

6 |

4 |

8 |

4 |

| IBM35 |

|

|

16 |

12 |

10 |

|

18 |

16 |

10 |

16 |

12 |

12 |

10 |

10 |

8 |

12 |

8 |

|

|