|

Head Injection

We presents proven injection molding technology for the benefit of tube manufacturers. This injection molding machine makes perfect edge of shoulder with high suface quality. Cost effective adaptability for round shape, oval and snap-on tubes. Minimized man power by fully automatic operation will ensure high investment ratio.

Features

- Servo drive is used for infeed conveyor which Enables zero deficity of sleeve feeding.

- Orientation function for oval tube and oriented cap.

- Clean and pricise orifice cutting divice.

- Faster color changing time.

- User friendly operating panel.

Index Unit

- Flexible modulized co-extruder and head block. Accurate thickness and uniformity.

- Excellent color dispersion even pearl color masterbatch.

Injcetion Unit

- Fine quality of sleeve surface achieved by our own designed calibrator and stable vacuum control.

- High efficient closed-loop cooling water circulation system gives shiny surface of sleeve.

Specification

| No. Of Cavity | IT-H228 | IT-H428 | IT-H632 |

|---|

| Cavity |

16~22 pcs/min |

32~44 pcs/min |

48~66 pcs/min |

| Tube Diameter |

Ø16~Ø60 mm |

Ø16~Ø60 mm |

Ø16~Ø60 mm |

| Tube Length |

60~200 mm |

60~200 mm |

60~200 mm |

Production Features

| MODEL | IT-H228 | IT-H428 | IT-H632 |

|---|

| Screw Diameter |

Ø28 mm |

Ø28 mm |

Ø32 mm |

| Hydraulic Oil |

50ℓ |

50ℓ |

70ℓ |

| Power Consumption |

7 kw |

10 kw |

14 kw |

| Air Consumption |

340ℓ / min |

470ℓ / min |

590ℓ / min |

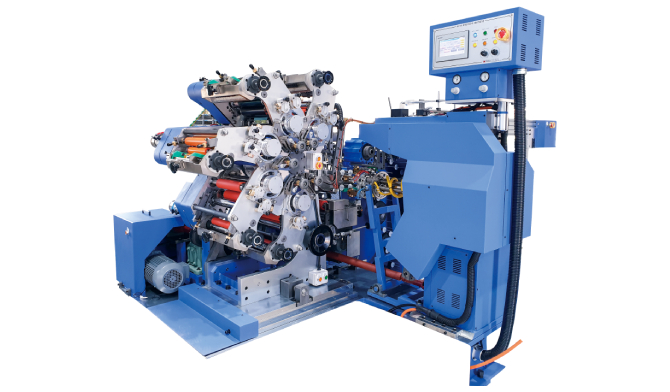

Offset Printer

As an well known technology, We offers improved technology of offset printing and lacquering

machine for extruded plastic tubes and sleeves.

Reliable performace ensure high-end attractive printing quality at high productivity.

Complete Printing, lacquering and drying in one machine.

Decoration by printing on tube is the most important for better appearance to consumers.

Features

- Surface pre-treatment by gas flame

- Gradiation in high quality.

- Easier and faster chage of printing plate and pint adjust.

- Starwheel type of feeder.

- Precise measured lacquering by very fine surface of anilox.

- UV curing for both ink and varnish.

Ink Transmission Unit

- High precision of each roller ensures perfect ink dispersion broadly.

- Easy control for gradiation.

Lacquering Unit

- Precise measured and broad lacquering by very fine surface of anilox.

- Accurate control for coating thickness.

Specifcation

| MODEL | WT-P580 |

|---|

| No. Of Blanket |

1 |

| No. Of Mandrel |

10 |

| Air Consumption |

460ℓ / min |

| Power Consumption |

14 kw |

Production Features

| MODEL | WT-P580 |

|---|

| No. Of Color |

5 Color |

| Capacity |

80 pcs/min |

| Tube Diameter |

Ø16~Ø60 mm |

| Tube Length |

60~200 mm |

Capping Machine

To meet customer's need We have develped un surpassed capping machine

by expertise through our many years of experience.

Features

- Screw and snap-on cap.

- Various torque adjustment for cap tightening.

- Tubes feed from stroage hopper automatically.

- Starwheel type drum feeder and pusher.

- Orientation by servo control and sensing.

- Top sealing function is available on capping machine.

- Aluminum or plastic laminated membrane punched and welded on top of tube precisely.

- Cap sorter and feeder for oriented snap-on cap.

- Automatic conveying system is available for connecting and synchronizing between head injection and capping machine.

Specifcation

| MODEL | IT-C600 |

|---|

| No. Of Mandrel |

12 |

| Air Consumption |

450ℓ / min |

| Power Consumption |

6 kw |

Production Features

| MODEL | IT-C600 |

|---|

| Applicable Cap |

Screw, Snap-On |

| Capacity |

70 pcs/min |

| Tube Diameter |

Ø16~Ø60 mm |

| Tube Length |

50~200 mm |

Hot Stamping

Hot stamp is a value added decorating for seamless and lami tubes. We Customer-oriented efforts and innovative technology delivers perfect quality of hot stamping machine. Ultrasonic Welding and Cutting Machine.

Features

- Reel Tape Feeder, tension control for hot stamp foil.

- Cartridge type of heater.

- Pressure control.

- Automatic Positioning for pint.

- Orientaton I-mark sensor.

Production Features

| MODEL | IT-S400 |

|---|

| No. Of Mandrel |

10 |

| Capacity |

40 pcs/min |

| Tube Diameter |

Ø16~Ø60 mm |

| Tube Length |

50~200 mm |

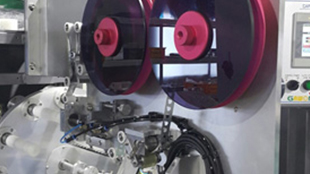

Ultrasonic Welding

We offers the most economic way of tube forming, seaming and cutting machine. Ultrasonic welding machine is suitable for both ABL and PBL tubes. ABL and PBL tubes are a light, hygienic and safe method of packaging that prevents leakage, provides UV protection and can also hold more aggressive products.

Features

- Forming tube sleeve by ultrasonic welding.

- Flexibility for both ABL and PBL tubes.

- Accurate cutting length.

- Low energy consumption.

- Lami tube has almost no limits of decoration due to flat sheet printing technology.

- Out ultrasonic welding machine can make sleeve up to 0.5mm thickness without distortion of printing and barrier.

- Servo drive technology is used for haul-off and cutting device which enables accurate length.

- Easy to control pressure and pressing time.

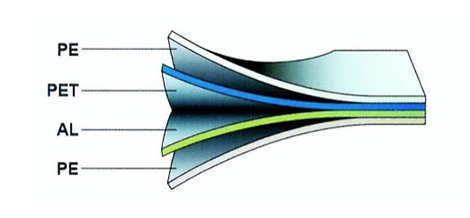

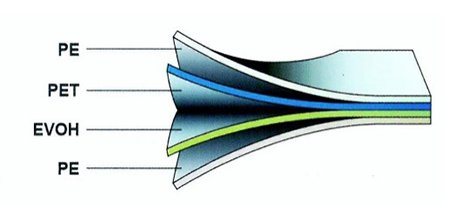

ABL & PBL

- Available for both ABL(Aluminum Barrier Laminate)sheet and PBL(Plastic Barrier Laminate) sheet without any limit of use.

PBL(Plastic Barrier Laminate)

ABL(Aluminum Barrier Laminate)

Specifcation

| MODEL | SW-W200-US | SW-W100-HF |

|---|

| Welding Method |

Ultra Sonic |

High Frequency |

| Power Consumption |

3 Kw |

18Kw |

| Machine Weight |

0.3 ton 3 |

ton |

Production Features

| MODEL | SW-W200-US | SW-W100-HF |

|---|

| Applicable Tube |

ABL, PBL |

ABL, PBL |

| Capacity |

16~22 sleeve/min |

100~150 sleeve/min |

| Tube Diameter |

Ø16~Ø60 mm |

Ø16~Ø60 mm |

| Tube Length |

50~200 mm |

50~200 mm |

Multi-layer Extruder

By extruding, making sleeve is the first step of seamless soft tube producing procedure.

And surface quality of sleeve is the first priority for valuable cosmetic tube.

Our accumulative technolgy delivers perfect surface even at high speed

Features

- Fast and easy tool change for diffent diameter of tube.

- Modulized calibrator for saving time and expense.

- Servo drive technology is used for haul-off and cutting device which enables accurate length.

- Faster color changing time.

- User friendly operating

Extruder & Head

- Flexible modulized co-extruder and head block. Accurate thickness and uniformity.

- Excellent color dispersion even pearl color masterbatch.

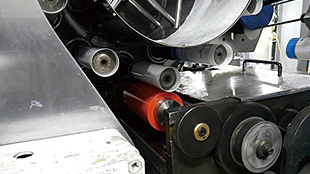

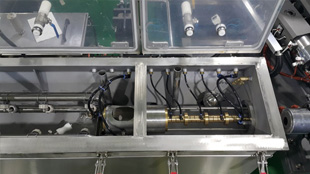

Vacuum & Cooling Tank

- Fine quality of sleeve surface achieved by our own designed calibrator and stable vacuum control.

- High efficient closed-loop cooling water circulation system gives shiny surface of sleeve.

Specifcation

| MODEL | SH-E200-1L | SH-E200-2L | SH-E200-3L | SH-E200-5L |

|---|

| No. Of Layrer |

1 layer |

2 layer |

3 layer |

5 layer |

| Connected Load |

59 kw |

96 kw |

132 kw |

121 kw |

| Cooling Water |

26,000 kcal |

26,000 kcal |

26,000 kcal |

26,000 kcal |

| Machine Weight |

3.5 ton |

4.3 ton |

5.2 ton |

6 ton |

Production Features

| MODEL | SH-E200-1L | SH-E200-5L |

|---|

| Tube Diameter |

Ø16~Ø60 mm |

Ø16~Ø60 mm |

| Tube Length |

50~250 mm |

50~250 mm |

| Line Speed |

16~20 m |

16~20 m |

| Capacity |

200 tubes |

200 tubes |

|

|