|

SBM Serise

SBM Serise will give our customers a broad choice in production capacity and price. SBM Serise requires minimum space and least energy consumption by full electric and pneumatic operation which enables high investment ratio together with environment friendly. Our aim is giving optimal solution to customers throughout continuous developing advanced technologlogy and best service along with sharing our experiences in field of PET bottle production.

Features

Economy

- Energy Saving (30 kW/Hr, SBM-4E)

- Fully Srevo System (6 servo moter)

- Compact Design (1.5 x 4.2 x 2.2 m)

- Fast Cycle Time (1200 cycle/Hr)

Superiority

- Wide Choice in Design For Quality Bottles

- Air Conditioning Inside Machine

- Safe & Silent Operating

- Dust Free & Oil Free

- Non Neck Blowing

Convenience

- Easy Control (touch screen)

- Safety & Environment Friedley

- Easy Preform Load (Turn Over Preform Loader, SBM-4E)

- Easy Operation, Maintenance & Mold Change At Floor

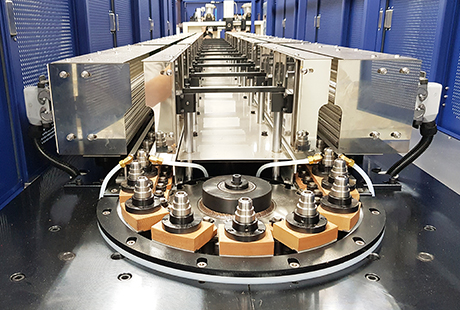

Reliabiblity & Economy

- Up to 10 rows of infrared halogen heater enables precise temperature control of preforms with non-contact temperature sensing. Strong structure and servo control ensure high quality products and low energy consumption.

- Stretch speed and position control by servo

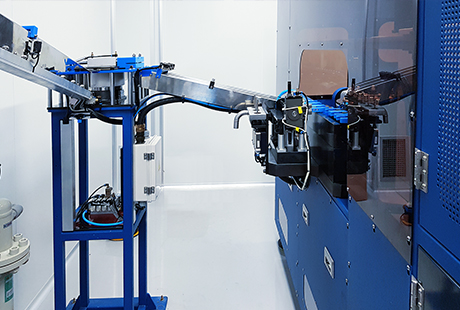

Superiority & Convenience

- Compact design takes up little space.

- Environmentally friendly quiet operation and safety.

- Stable preform transfer and easy control.

Bottle & Preform Molds

Specification

| Specification | Unit | SBM-1E | SBM-2E | SBM-3E | SBM-4E | SBM-6E | SBM-4SE | SBM-6SE | SBM-8SE |

|---|

| Number Of Cavity |

Cavity |

1 |

2 |

3 |

4 |

6 |

4 |

6 |

8 |

| Preform Neck Dlameter |

mm |

Ø15~38 |

Ø15~38 |

Ø15~38 |

Ø15~30 |

Ø15~30 |

Ø15~30 |

Ø15~30 |

Ø15~30 |

| Preform Length |

mm |

75~180 |

75~180 |

75~180 |

75~180 |

75~180 |

75~120 |

75~120 |

75~120 |

|

Bottle Diameter max.

|

mm |

Ø120 |

Ø120 |

Ø120 |

Ø110 |

Ø110 |

Ø75 |

Ø68 |

Ø68 |

| Bottle Length max. |

mm |

340 |

340 |

340 |

340 |

340 |

220 |

220 |

220 |

| Cavity Mount Pitch |

mm |

- |

140 |

140 |

120 |

120 |

90 |

72 |

72 |

| Electrical Power |

|

3Phase | 220V / 380V / 440V | 50Hz/60Hz |

| - Mechanical Movement |

KW |

4.5 |

4.5 |

5.5 |

5.7 |

6.5 |

5.5 |

5.7 |

6.5 |

| - Heater |

KW |

20.0 |

20.0 |

40.0 |

40.0 |

66.0 |

40.0 |

40.0 |

66.0 |

| - Total Connected Load |

KW |

24.5 |

24.5 |

45.5 |

45.5 |

72.5 |

45.5 |

45.7 |

72.5 |

| - Average Power Consumption |

KW |

16.0 |

18.0 |

30.0 |

33.0 |

50.0 |

30.0 |

33.0 |

45.0 |

| Compressed Air |

|

|

|

|

|

|

|

|

|

- Mechanical Movement

(7kg/ cm²) |

NL/min |

220 |

250 |

280 |

280 |

400 |

300 |

400 |

430 |

| - Blowing (25kg/ cm²) |

NL/min |

850 |

1650 |

2500 |

3300 |

4800 |

1800 |

2100 |

1700 |

| - Blowing (30kg/ cm²) |

NL/min |

1000 |

1900 |

2900 |

2900 |

5500 |

2100 |

2500 |

3100 |

| - Blowing (38kg/ cm²) |

NL/min |

1300 |

2500 |

3800 |

3800 |

7300 |

2700 |

3100 |

4000 |

| Mold Cooling |

Kcal/Hr |

1300 |

2500 |

3500 |

3500 |

5500 |

3000 |

3200 |

4500 |

| - Cooling Water Flow(3cm²) |

L/min |

15 |

15 |

20 |

20 |

25 |

20 |

20 |

25 |

| Oven Unit Cooling |

Kcal/Hr |

2500 |

2500 |

4500 |

4500 |

6500 |

4500 |

4500 |

6500 |

| - Cooling Water Flow (3kg/ cm²) |

L/min |

25 |

25 |

30 |

30 |

40 |

30 |

30 |

40 |

| Machine Dimension (W×L×H ) |

m |

1.4×2.7×2.2 |

1.4×2.7×2.2 |

1.4×3.9×2.2 |

1.4×4.2×2.5 |

1.4×5.9×2.7 |

1.4×3.9×2.5 |

1.4×4.3×2.5 |

1.4×5.6×2.7 |

| Machine Weight |

ton |

2.3 |

3.0 |

4.2 |

4.5 |

5.5 |

4.2 |

4.5 |

5.5 |

| Products Figures | Unit | SBM-1E | SBM-2E | SBM-3E | SBM-4E | SBM-6E | SBM-4SE | SBM-6SE | SBM-8SE |

|---|

| 0.5L |

BPH |

1250 |

2400 |

3600 |

4800 |

7000 |

4800 |

7200 |

9000 |

| 0.75L |

BPH |

1250 |

2400 |

3600 |

4800 |

7000 |

4800 |

- |

- |

| 1.0L |

BPH |

1200 |

2300 |

3500 |

4600 |

6700 |

- |

- |

- |

| 1.5L |

BPH |

1100 |

2200 |

3300 |

4400 |

6600 |

- |

- |

- |

| 2.0L |

BPH |

1000 |

2000 |

3000 |

4000 |

6000 |

- |

- |

- |

| 3.0L |

BPH |

700 |

- |

- |

- |

- |

- |

- |

- |

|

|