|

Multi-Layer Tubes for Medical

Precise resin distribution by advanced melting pump and integrated control system contributes to the medical industry which requires high precision and quality stability.

Application

- [Catheter, IV Solution, Serological Pipette, etc.]

Specifcation

| Tube EXT | Stripe EXT | Outer Layer EXT | Middie Layer EXT | Inner Layer EXT |

|---|

| Extruder |

|

20mm |

15mm |

50mm |

25mm |

25mm |

| Line Speed |

M/Min |

5~40 |

15~30 |

| Tube Dia |

Ø |

1 |

~15 |

| Electric Power |

Kw |

15 |

5Kw |

| Water Chiller |

|

40L/Min at 10℃ |

50L/Min at 10℃ |

| Dimension |

W × L × Hmm |

4000 × 1500 × 3000 |

3500 × 10000 × 2500 |

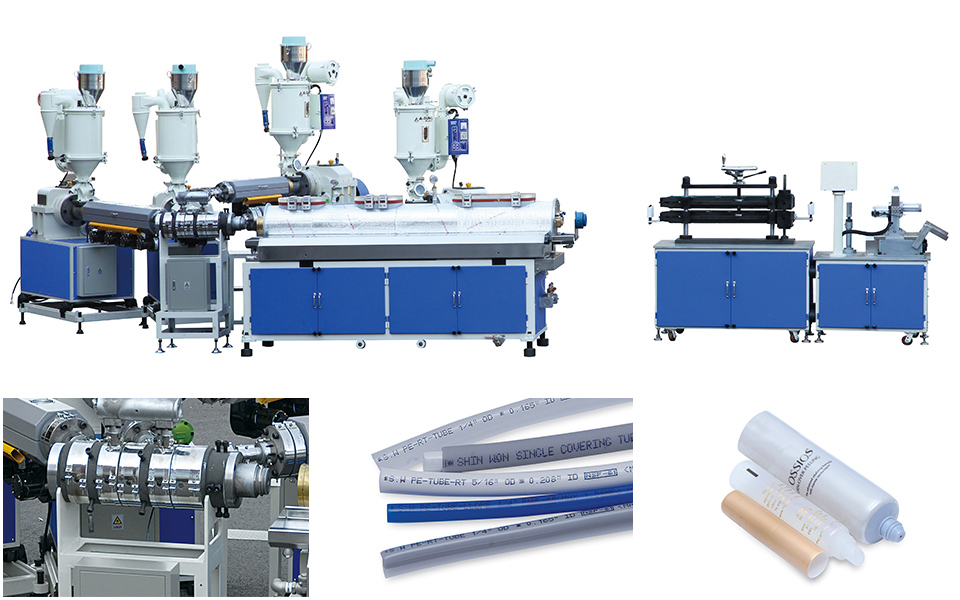

Multi-Layer Tubes for Cosmetics

As the first step, extruded sleeve quality is the most prior concern in cosmetics tube making process. Our unique designed 5-Layer head contributes excellent surface and precise distribution of each layer's thickness. Furthermore advanced technologies and controls will lead high productivity and saving costs.

Specifcation

| Mono-Layer

|

|---|

| Extruder |

|

70mm |

| Line Speed |

M/Min |

3~7 |

| Tube Dia |

Ø |

16~25 |

| Electric Power |

Kw |

45Kw |

| Water Chiller |

|

40L/Min at 10℃ |

| Dimension |

W × L × Hmm |

1500 × 6000 × 2500 |

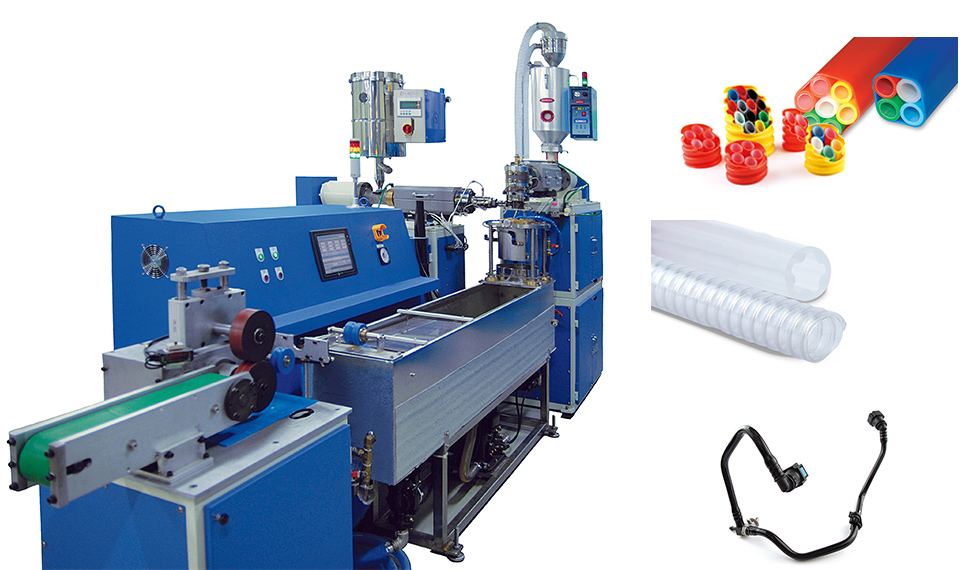

Industrial Pipes / Hoses

Our long experience and accumulated technology will meet various needs of customers.

Superior durability and excellent perfomance enables broaden customers choice.

Application

- [Fuel Tube, Corrugated Optical Duct, Micro Duct, Braided Hose, etc.]

Specifcation

| Inner Duct | Outer Duct |

|---|

|

PE EXT |

Silicion EXT |

PE EXT |

| Extruder |

|

90mm |

60mm |

90mm |

| Line Speed |

M/Min |

8~15 |

0.8~1.5 |

| Tube Dia |

Ø |

20~50 |

30~200 |

| Electric Power |

Kw |

140 |

100 |

| Water Chiller |

|

80L/Min at 10℃ |

80L/Min at 10℃ |

| Dimension |

W × L × Hmm |

5000 × 15000 × 3300 |

4000 × 20000 × 33000 |

|

|